GASEOUS SUPPRESSION SYSTEM

Gaseous fire suppression also called Clean agent Fire Suppression System is a term to describe the use of gases and chemical agents to extinguish a fire. These Agents are governed with different standards and regulations in the world. The system typically consists of clean agent, agent storage containers, gas release valves, fire detectors, fire detection system, gas release panel, Manual call points, Abort switch, agent delivery piping, and agent dispersion nozzles. Gas Suppression Systems are generally used in concealed rooms. The principle used by Gas Suppression System is by breaking the Fire Triangle, the fire ceases to exist. In the room, protected by Gas Suppression System, there are various detectors placed at various locations.

Various Gases used in Gas suppression systems are Inergen, CO2, FM200, NOVAC, Aerosol, N2, etc.

This system has certain features such as :

- Quick discharge and flooding into Protected room within 60 seconds.

- Timer delay between Alarm and discharge of agent.

- It can be aborted during Timer delay, in case of false alarm.

- Actuation is possible by way of Electrical, Pneumatic or Manual actuation.

Typical areas of Application :

- Server Rooms

- Data Centres

- Control Rooms

- UPS, Battery rooms

- Indoor Transformer Protection

- Generators,

- Hydraulic machine rooms, Paint booths, etc

HP / LP CO2 :

This is the most efficient of all fire suppression systems in the market today. It suppresses a fire by cooling and depleting oxygen from the fire, thus removing the essential Heat and Oxygen Fire needs.

CO2 fire suppression systems are an ideal solution for local fire suppression applications. This agent is suitable for both local applications as well as total flooding applications.

The CO2 fire suppression agent is one of the oldest and most effective fire fighting solutions used within this industry.

Applying safe and correct designs, including all safety procedures, this fire suppression system is the most effective solution available for most applications.

CO2 fire suppression systems rapidly cool the risk within the first minute of discharge, then an extended discharge removes oxygen and effectively INERTS the protected risk.

When CO2 systems are activated, the agent becomes white as it condensates in the warmer protected environment. The condensation clears overtime and the CO2 gas becomes invisible. Due to the colourness and odourless charactoristics of the gas, it is essential add odourisers to the discharge pipe work so that the agent is scented as the CO@ system discharges into the risk.

Advantages of using CO2 are :

- Non-corrosive

- Non Conductive

- Zero Ozone Depletion

- Zero Global Warming (as fire suppression CO2 is nor taken from a fossil fuel)

- Easily distributed

- CO2 can be used as a common bank arrangement with diverter/distribution valves directing it to multiple enclosures

Application of Co2 System :

- Indoor Transformer Protection

- Paint booths

- paint mixing rooms

- Generators

- Engine test stands

- Machining centres and many more

FM 200 :

FM 200 is a reliable solution based on HFC 227ea, an extinguishing agent known around the world.

Built on 42-bar technology, these Gas Suppression Systems are efficient and space-saving. Whether for the valuable systems, data, people or the working environment, this Gas Suppression System provides optimum protection in case of fire and helps ensuring business continuity. The extinguishing agent of this Gas Suppression System is very effective and works at low extinguishing concentrations to protect people and assets. The extinguishing agent is chemically inert and has low electric conductivity. This Gas Suppression Systems provides ideal protection especially for areas with electrical and electronic risks of fire.

NOVAC System :

NOVEC is an inert gas with negligible atmospheric life, zero ozone depletion and innovative solution used as Extinguishing agent to protect assets from the risk of fire damage in critical applications and sensitive equipment. It works on principle of cooling and it reduces the oxygen in atmosphere. Extinguishing agent NOVEC Fire Protection Fluid absorbs sufficient heat to upset the balance of the fire. This cooling effect is supported by the oxygen reduction in the flame due to the volumetric expansion of the molecules. The high efficiency of the NOVEC system allows using a low extinguishing concentration. As a result, needs lesser quantity of NOVAC gas to be stored in Cylinder and less number of cylinders are required to safely protect rooms. Fewer cylinders and less space are needed for installation and storage because the liquid agent NOVEC fluid is stored in cylinders pressurized with 42-bar nitrogen.

Inergen systems

Inergen fire suppression is a blend of naturally occurring gases; Nitrogen, Argon, & a small amount of carbon dioxide. The Inergen is made up of all these gas with a blend mix consisting of Argon 50%, Nitrogen 42% and CO2 8%

INERGEN is a highly effective fire suppression system for extinguishing fire & preventing re-ignition with no risk to people or damage to equipment if engineered and installed by a qualified fire suppression systems installation company.

The INERGEN fire suppression also has no adverse affect on the ozone layer as it is completely made up of naturally occurring gases.

INERGEN fire suppression systems also have a zero global warming potential, & no atmospheric lifetime.

An INERGEN system is certified as a safe and clean fire suppression system for occupied spaces

Medically evaluated by leading authorities around the world, the blend of INERT gases maintains normal blood-oxygen levels, thereby ensuring heart rate & mental performance remain optimal to ensure a safe escape during or after a fire suppression system discharge.

Unlike many other suppression systems which need to be located close to the protected area, INERGEN can be stored up to further away, & as it is organic in structure it is not subject to time use limiting restrictions.

INERGEN fire suppression is stored & discharged as a gas, when the fire suppression system discharges the INERGEN gas, it is clear, insuring a safe & visually un-obscured exit.

Various Applications of Inergen system

- Laboratories

- Telecommunication rooms

- Computer & server room

- Control rooms

- Archives

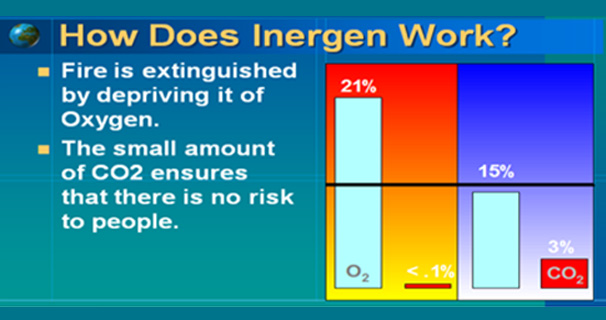

How Does Inergen System Work

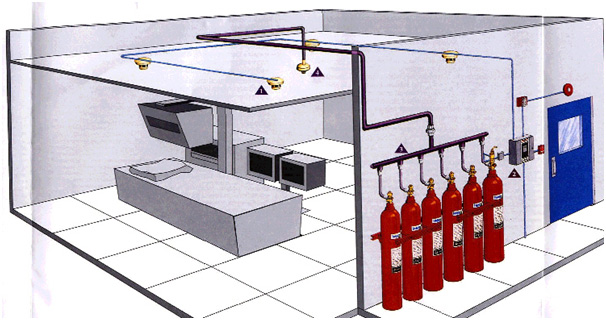

Typical Arrangement of Inergen system

Aerosol Based Gas flooding System :

The condensed aerosol fire suppression technology came into prominence as a result of the 1994 Montreal Protocol. The international treaty banned ozone depleting substances, such as Halon and other halocarbon- and chlorofluorocarbon-based substances. Thus, our fire protection technology offers a sustainable future for humanity. We are Authorised channel partner of FirePro Aerosol system.

Advantages are :

- 15-year Product Life

- Non-Pressurized

- Non-Oxygen Depleting

- HFC-free

- CFC-free

- Zero Global Warming Potential

- Halon Alternative

- Zero Ozone Depletion Potential

- Manufactured Under ISO 14001 / 9001 Standards

Aerosol System :

Water Mist System :

This is a simple but effective fire suppression solution. Water misting fire suppression solutions work only when the heat is sufficient to draw in the micro particles of water.

As the heat intensifies, water droplet particles are drawn into the fuel/heat mixture and this creates a cooling effect and the fire is extinguished or suppressed.

Water mist fire suppression has limited uses and is not suitable for IT infrastructures or in applications which will be harmed by the post discharged reformed water droplets.

There are two water mist systems available; High Pressure and Low Pressure.

The Benefits :

With any fire alarm activation in public places or buildings, we automatically think of the traditional water sprinkler system. But the traditional sprinkler system as an effective method of fire suppression has moved on.

Water Mist Applications Include :

- Gas Turbines

- Fuel storage

- Restaurant and commercial catering

- Data centers

- Chemical Stores

- Engine Test Beds